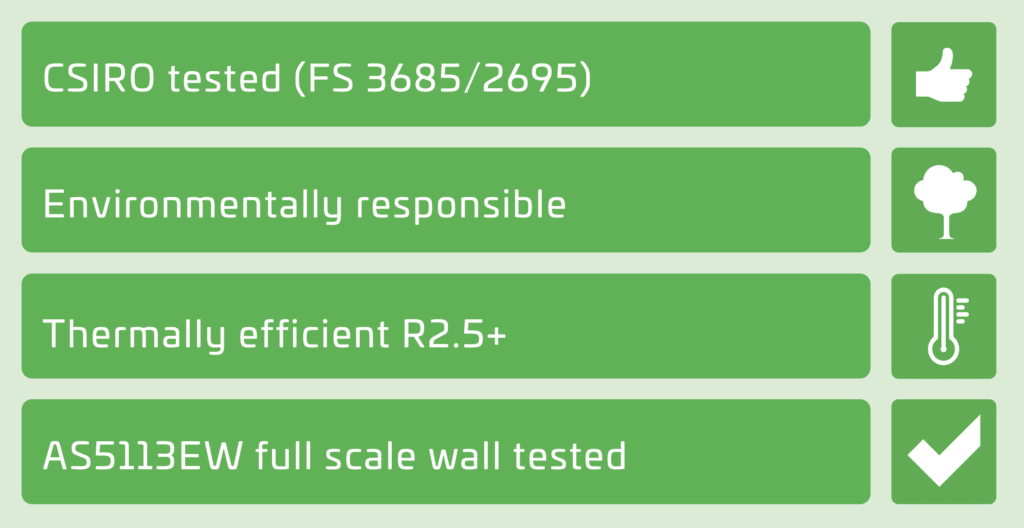

QT EcoSeries Wall Panel is a solid substrate that is fire-resistant with outstanding thermal and acoustic qualities. Designed and manufactured in Australia from Conpolcrete (a cementitious mixture containing recycled EPS) QT EcoSeries Panel is lightweight and strong, withstanding wind gust above 250k/ph.

Full Scale AS:5113-EW Approved

FACT: Very few other products, including most Deemed to satisfy products, have successfully passed the AS5113-EW Full Facade test.

What is QT?

The QT Systems EcoSeries Wall Panel is a lightweight masonry-veneer wall cladding system suitable for Type A and B construction in Australia. The wall panel offers a solid substrate that can accommodate a wide range of finishes.

Download Technical Data

Extensive DIY, technical data, videos and brochures can be found in the Austech Resource Centre.

Click the link to download Download All Technical Data

This system provides an accurate method of predicting the ability of a wall to maintain its strength in a fire and to resist the spread of the fire, an FRL of 90/90/90 means a minimum fire resistance period of 90 minutes each for structural adequacy, integrity and insulation.

Click the link to download Australian Standard 5113 Fire Propagation Testing

Warrington Fire Research Fire Resistance Test of a 50mm thick QT EcoSeries exterior wall panel system tested in accordance with AS1530.4-2005

Click the link to download

The QT 50mm Conpolcrete panel was tested in accordance with BS 84142-2015 as modified by AS 5113-2016 and Amendment 1:2018 and document by Ignis Lab.

Click the link to download Render

The product as supplied is non-hazardous. However, dust from this product when cut, sawn, abraded contains crystalline silica which may be respirable and is hazardous.

Click the link to Download Safety Data Sheet

The QT 50mm Coonpolcrete panel was tested in accordance with BS 841412-2015vas modified by AS 5113-2016 and Amended 1:2018 and documented by Ignis Labs.

Click the link to download AS5113 2020 Ignis Lab Test

This technical manual cover the QT EcoSeries Wall Panel, a masonry veneer wall cladding system with a cavity.

Click the link to download QT EcoSeries Manual

The sound transmission loss (TL 399) of a timber stud wall system lined with a proprietary concrete composite material.

Click the link to Download CSIRO Airborne Sound Transmission

Resistance to wind pressures for non-cyclone regions up to the strength limit state pressures of 4.44 kPa.

Click the link to download Face Load Wind Pressure

The CSIRO has conducted the test 3837 for smoke and heat release.

Click the link to download CSIRO Heat and Smoke Certification

The purpose of this assessment is to report the applicable use and compliance of the QT Panel external wall board against the requirements of the National Construction Code – Volume One – Building Code of Australia, 2019 (BCA) through Verification Method CV3.

Click the link to download VOC Adviser Satisfaction

Ignis Solutions has been engaged by QT Systems to undertake a review its suitability in applications of bushfire prone areas and its compliance for use on external walls with AS 3959:2018 for BAL 12.5 to BAL FZ and thus compliance with National Construction Code Building Code of Australia Volume One Clauses GP5.1, G5.0, G5.1 and G5.2 and Volume Two Part 3.10.5 and 3.10.5.0 2019.

The QT Panel are constructed of 50mm Conpolcrete, a cementitious mixture containing recycled polystyrene. The QT Panel is fixed to a stud frame. The QT Panel is to be rendered by an appropriate and tested render system.

Click the link to download BAL FZ

Product Comparison 1

| Cladding Type | Conpolcrete Type | AAC Concrete Type | Fibre Cement Type | Polystyrene Type |

|---|---|---|---|---|

| Size (mm) | 2250 x 900 | 2400 x 600 | 2440 x 1200 | 2400 x 1200 |

| Thickness (mm) | 50 | 50 | 8 | 50 |

| Recycled | 70% (by volume of material) | None | None | None |

| Cavity (mm) | 20 | 40 | 16 | None |

| Sarking | Vapour permeable | None | Vapour permeable | Vapour permeable |

| Battens | Timber / Metal | Metal | Metal | None |

| Batten Direction | Vertical | Horizontal | Horizontal | N/A |

| Cutting | Hand Saw | Diamond blade | Masonry blade | Hand Saw |

| Fixing | Face button and Screw | Rear masonry screws | Face Screws | Face button and Screw |

| Jointing | Expanda Foam | AAC Adhesive | Edge to Edge | Expanda Foam |

Product Comparison 2

| Tests Implemented | QT Systems EcoSeries Panel (50mm) | AAC Panel (50mm) | Clay Brick (110mm) | Concrete Block (190mm) | Polystyrene (50mm) | Fibre Cement Sheet (9mm) |

|---|---|---|---|---|---|---|

| Fire Resistance Level (FRL) | Yes | Yes | Yes | Yes | No | No |

| 90/90/90 or better | 90/90/90 | 90/90/90 | Not all brick can be used in Fire Walls | 120/120/120 if core-filled with Concrete | N/A | N/A |

| Bushfire Attack Level (BAL) | Yes | Yes | Yes | Yes | Yes | Yes |

| FZ=Flame Zone | As per AS 3959 part 9.4.1c | N/A | N/A | N/A | Boundary Wall system required to achieve AS 3959 | |

| No Spread of Flame Reference | Yes | Yes | Yes | Yes | Yes | Yes |

| No Spread of Flame Reference | AS1530.3 Ignitability Index = 0 Spread of Flame Index = 0 Heat Development = 0 Smoke Developed = 0-1 | AS1530.3 Ignitability Index = 0 Spread of Flame Index = 0 Heat Development = 0 Smoke Developed = 0-1 | AS1530.3 Ignitability Index = 12 Spread of Flame Index = 0 Heat Development = 3 Smoke Developed = 0-5 | AS1530.3 Ignitability Index = ? Spread of Flame Index = 0 Heat Development = 0 Smoke Developed = 5 |

||

| High Thermal Efficiency | Yes | No | No | No | Yes | No |

| K-Value Reference (Lower value = Higher Insulation) | Thermal conductivity 0.07m²K/W | Thermal conductivity 0.156W/m²K | Thermal conductivity 1.63m²K/W | Thermal conductivity 0.963m²K/W | Thermal conductivity 0.044m²K/W | Thermal conductivity 3.125m²K/W |

| R-Value Reference (Higher Value = Higher Insulation) | (50mm) R Value = 0.714 W/m²Kt | (50mm) R Value = 0.313 W/m²K | (50mm) R Value = 0.030 W/m²K | (50mm) R Value = 0.052 W/m²K | (50mm) R Value = 1.13 W/m²K | (50mm) R Value = 0.016 W/m²K |

| Other Benefits | ||||||

| Super light-weight | Yes | No | No | No | Yes | Yes |

| Less than 20kg/m² | 50mm = 19kg/m² Based on material density of 380kg/m³ | 50mm = 28kg/m² Based on material density of 561kg/m³ | Approx 200kg/m² Based on average brick weight of 4kg | Approx 180kg/m² Not corefilled | 50mm = 0.675kg/m² Based on SL Grade material density of 13.5kg/m³ | 9mm = 11.5kg/m² Based on material density of 1285kg/m³ |

| Quick and easy installation | Yes | No | No | No | Yes | Yes |

| Eco-Friendly | Yes | No | No | No | No | No |

QT EcoSeries Cladding Outperforms all Competitive Panels in 8 Key Areas.

Better Thermal Performance

Excellent Sound Abatement

High Fire Resistance tested to AS:5113 EW

Lighter Weight – 40% less than other panels

Thinner Dimension – 50% less than other panels

Greater Versatility – no hidden steel

Faster Installations

More Cost-effective

Email us with your project plans, so we can guide you through our collection of technical data, scientific journals and manuals. We will send you a link to download all the files you need.

11 Bowen Cr

West Gosford, NSW 2250

Phone: 02 9831 1623

Queensland

145 Tile Street, Wacol, Qld 4076

(Dynamic warehouse logistics)Austech Ph: 07-3268-3066